Introduction:

As the first commercial models of wind turbines that are still standing today, are reaching 30 years of service, turbine owners begin to face the challenge of either continuing to maintain and optimize these older wind turbines or dismantle them. There comes a certain point where expenses to maintain the wind turbine might overdue the turnover from energy production. Some of the critical components that often require attention within wind turbines, are among others the mainframe, flanges, bolts and yaw rings. Traditionally, damages to some of these components on older turbines has led to the consideration of dismantling, if the turbines have outlived their designed lifetime and the guarantee-period from the developer is expired. This is where we at 3WIS offer our conceptual repair solutions, a proactive procedure that reinforces bearing steel structures, where deterioration appears. Wind turbine owners hereby can extend the lifetime of their assets with up to 10 years, hereby achieving increased return on their investment while reducing the environmental impact from decommissioning or installing new turbines.

What to consider when prolonging the lifetime of your assets

Taking all scenarios into account, here are some key figures that turbine owner should make when considering extending the life of their assets:

Calculating TOC is relative for each turbine, depending on wind site affecting the average AEP (Annual Energy Production), general condition of the other components on the turbine, potential local tariffs, and more.

The Impact of Reinforcing Solutions

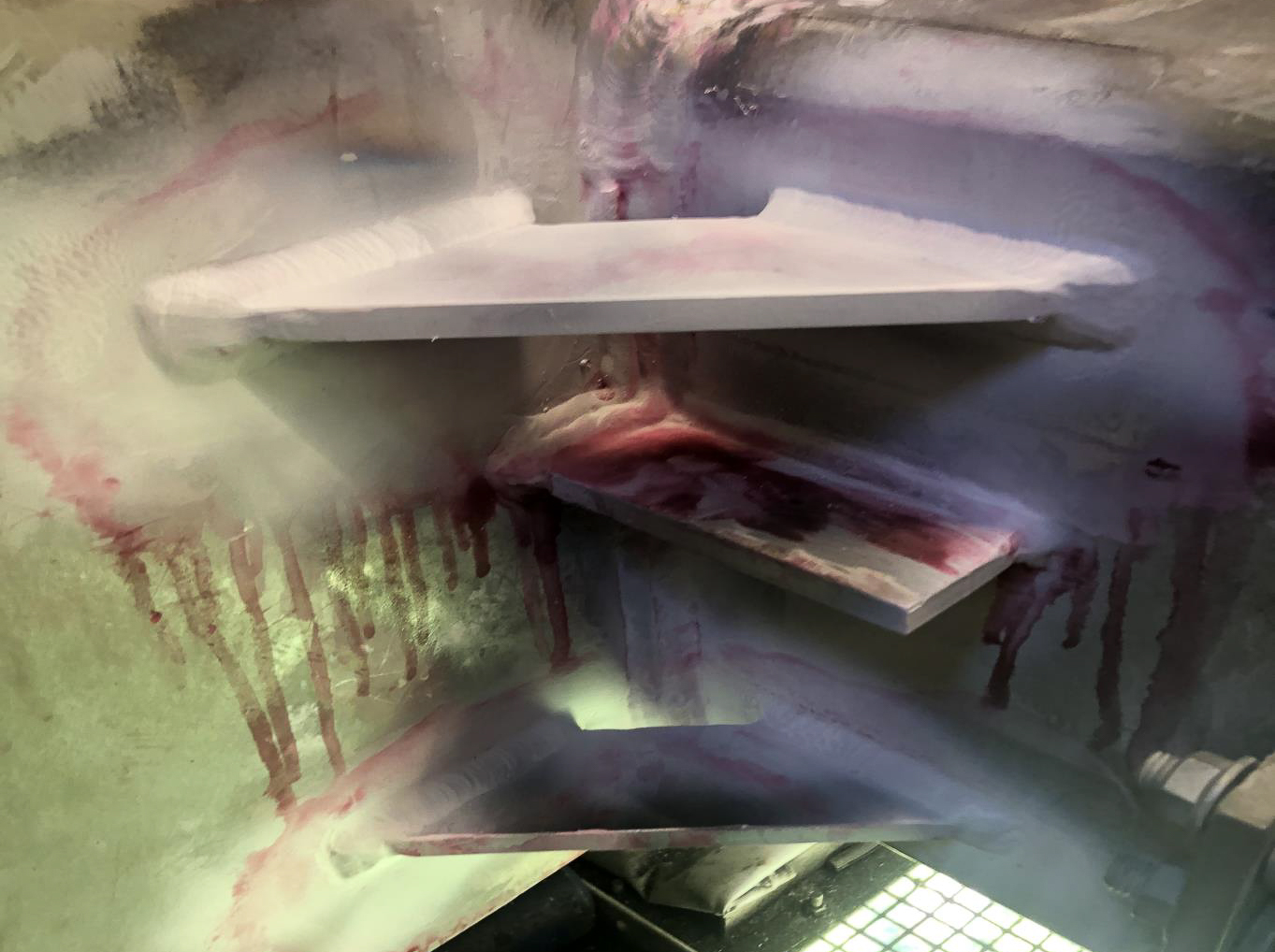

Deterioration of exposed structures in older wind turbines or new turbines in general can be a quite concerning issue for turbine owners. In the past, damages to crucial components often meant extended repair and downtime, involving removement of the nacelle with heavy lifting equipment (among others) and replacing the damaged components. Hereby resulting in significant financial losses and contributing to environmental waste as well. However, by investing in reinforcing solutions, owners can now significantly extend the lifetime of their assets.

Preventive maintenance through Core Integrity Testing

One of the solutions we provide at 3WIS is a preventive maintenance-based multipoint inspection of exposed areas, at an early stage. Preventive maintenance through on-going NDT inspections, may also be a solution that helps service companies as part of their core integrity checks, as well as turbine owners, in maintaining quality- & safety demands from their insurance companies. Adopting a procedure that reinforces the mainframe aligns with regulatory standards and certification requirements. he turbine in peak condition and in compliance with safety guidelines, enhancing the credibility within the wind energy sector.

Maximizing Return on Investment:

The implementation of the proactive procedure for reinforcing exposed structures allows wind turbine owners to protect their investments and increase their return on invest over more years. By addressing deterioration at an early stage, operators can prevent further damage, costly repairs, and unplanned downtime, through a cost-friendly and fast reinforcement procedure. If other mechanical or electrical parts of the turbine is in good condition, reinforcement of exposed structures is a cost-friendly and highly beneficial solution.

Environmental Benefits:

Sustainable development requires the optimization of existing resources and minimizing waste. Extending the life of older wind turbines through reinforcement of the mainframe is a solution that contributes to a significant reduction in the environmental impact associated with producing new turbine. The mainframe is a highly exposed steel structure of the wind turbine, that most turbines experience within their designed lifetime. By keeping functional turbines in operation, the industry can decrease the amount of waste that the industry produces, through manufacturing processes, and energy consumption involved in building new units.

Conclusion:

Wind turbine owners face the dual challenge of either keeping their turbines running or dismantling them when they have reached their designed lifetime and that service and repair expenses exceed turnover from energy production. The implementation of a procedure such as reinforcing exposed steel structures, when deterioration appears, represents a significant step towards keeping older turbines running. By extending the life of older wind turbines by up to 10 years, operators can continue to generate more renewable energy and therefore improving total cost of ownership while simultaneously reducing the environmental impact of installing new turbines. Embracing these reinforcing solutions underscores the wind industry's commitment to sustainability, safety, and responsibility of resources, paving the way for a greener and more resilient exploitation of wind power.