Repairing the transformer is a cost-efficient solution, compared to exchanging the damaged unit. In most cases with leaking transformers, we are able to repair the transformer, using our specialized welding repair method. Our method is designed to reduce both downtime and cost of ownership, and thereby maximizing the availability and performance of your assets.

We have many years of experience within the field of welding repair sol

utions and hundreds of transformers still operating today. Our skilled employees are highly trained to carry out the procedure, making sure that the transformers can continue to operate without leakages and without the need for replacement.

The repairing process is smooth and fast and is performed without any drainage of the transformer. Depending on the leaks, the timeframe of the repair is typically 2-5 days, from inspecti- on of the transformer to completion of the final documentation.

1. Detection & inspection

The leaks are typically detected during an inspection, which leads to further inspections to identify and map the leaks. The process is fully documented.

2. Repairing process

Repairing the leaks, using special developed on-site welding methods, thus reducing both downtime and costs significantly.

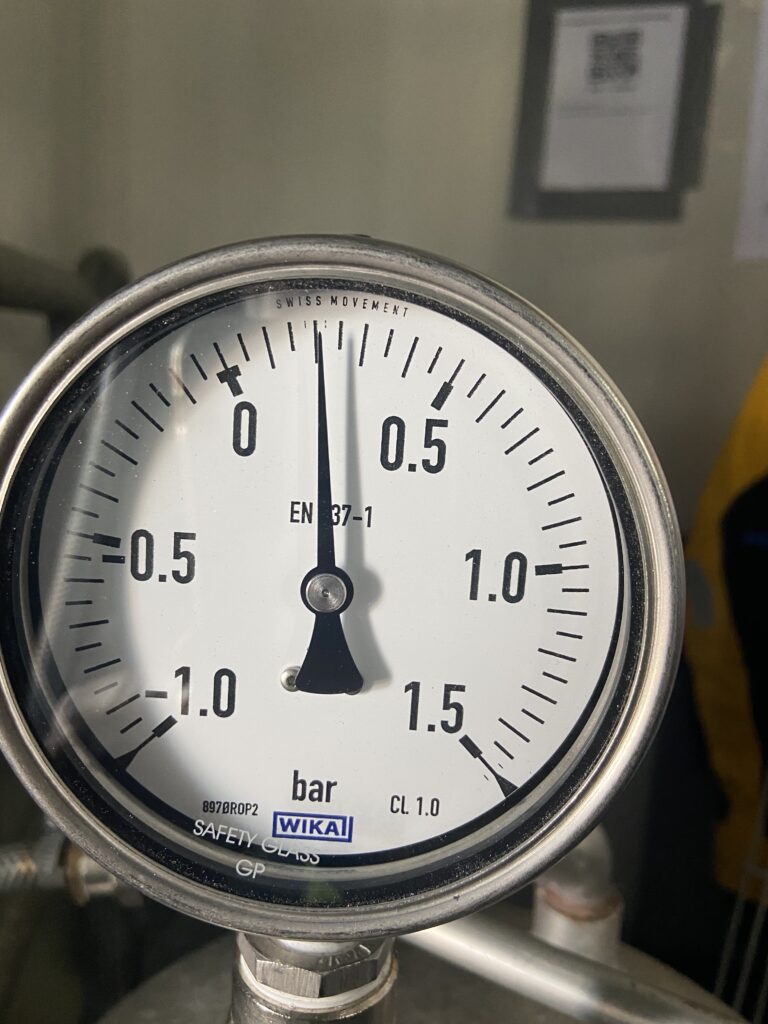

3. Testing & documentation

Pressure testing and documentation to ensure that the transformer is sealed. The welding repair of the transformer is completed and documented.

Contact us for more information about the repair method. Find our contact info right here